RDS Product Design Capabilities:

Innovating Solutions for Extreme Environments

At RDS, our product development expertise turns ideas into robust, high-performance solutions built for demanding environments.

Backed by decades of engineering expertise and certified processes, we deliver comprehensive design support across market sectors.

From early concept work through to production-ready systems, we combine advanced technology, engineering precision, and sector-specific knowledge to create products that perform reliably in harsh and mission-critical conditions.

Whether you need a rugged embedded platform, an advanced HMI with integrated touch, or a connected IoT device, we work closely with you to deliver innovative, dependable, and market-ready solutions.

Conceptual Design and Feasibility

Every successful product begins with a clear vision and a robust technical roadmap. Our conceptual design phase is dedicated to de-risking your project from day one, ensuring that innovative ideas are grounded in engineering reality and market viability through collaborative partnership.

- Ideation and Specification: Collaborate with our engineers to define requirements, explore concepts, and assess technical feasibility for your project.

- 3D Modeling and Simulation: Advanced CAD tools and simulation software to visualise designs, optimise performance, and identify potential challenges early.

- Proof-of-Concept Prototyping: Rapid development of functional prototypes using in-house 3D printing and PCB design to validate ideas and refine specifications.

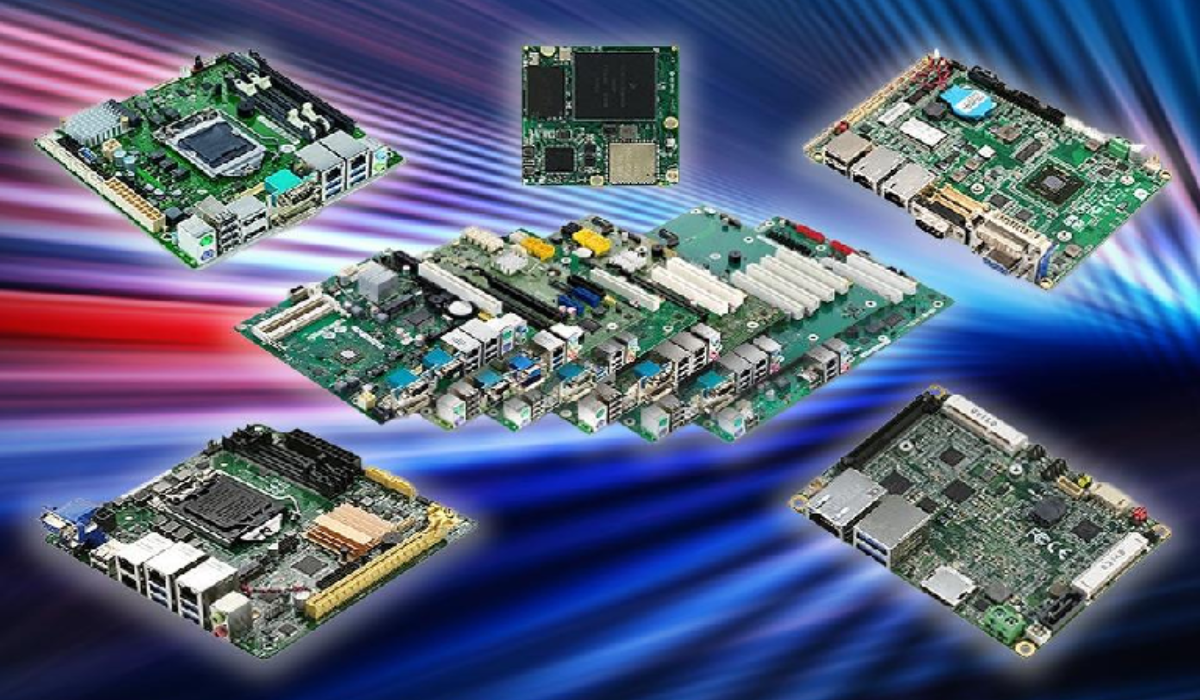

Custom Electronics Design

When standard off-the-shelf hardware cannot meet specific performance, power, or environmental requirements, custom electronics design provides a tailored alternative. Our engineering team specialises in developing bespoke hardware platforms that are perfectly aligned with your application’s processing needs and long-term reliability goals.

- Embedded Systems: Design bespoke single-board computers (SBCs), Box PCs, and microcontrollers with Intel, AMD, or ARM processors, tailored for power efficiency and performance.

- IoT and AI Integration: Incorporate edge computing, machine vision, and secure IoT connectivity for smart applications like predictive maintenance and automation.

- Firmware Development: Custom firmware and embedded OS (Windows, Linux, RTOS) optimised for your hardware, with secure OTA update capabilities.

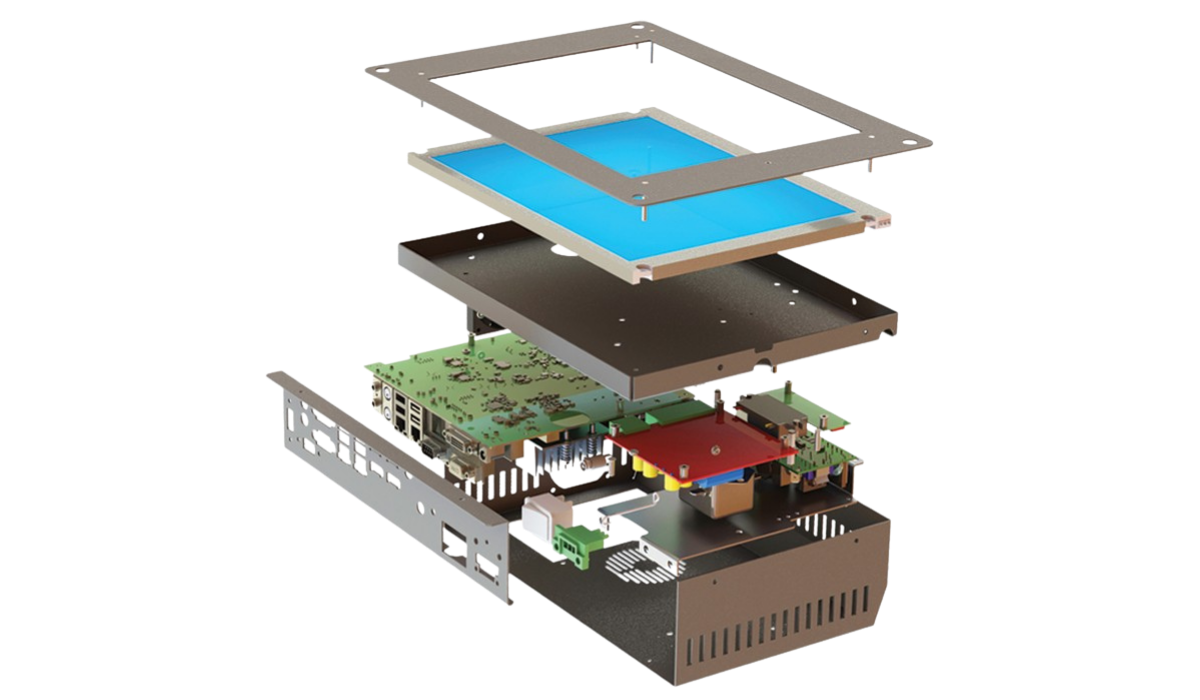

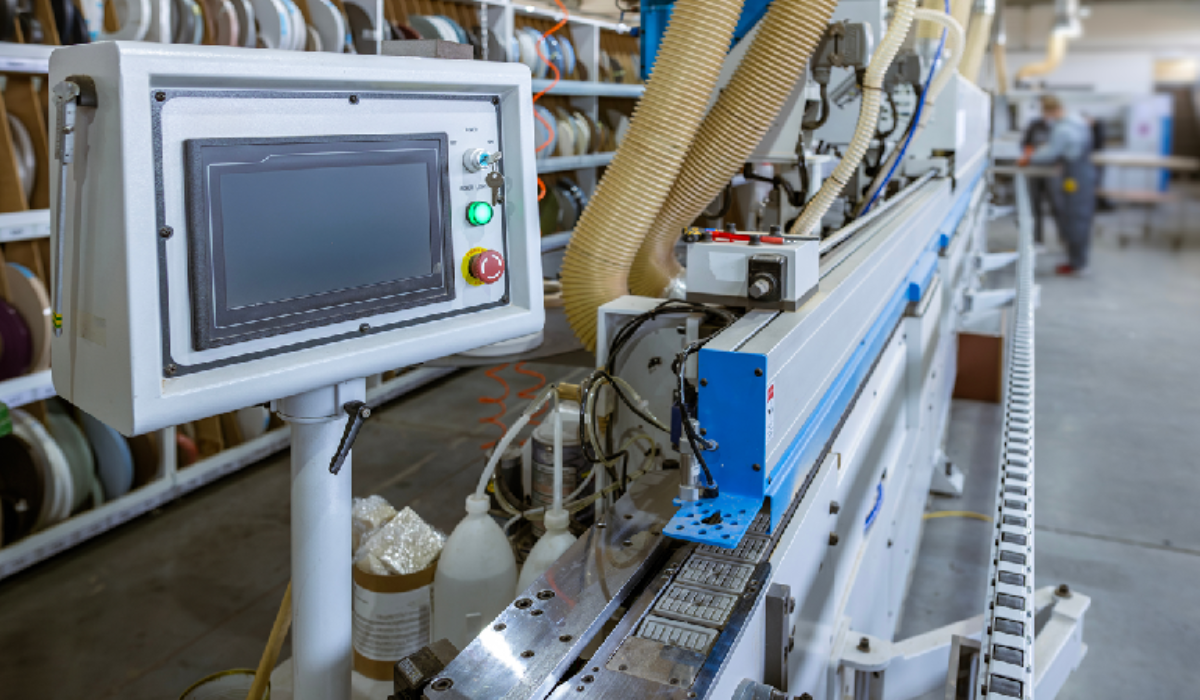

Display and HMI Design

The Human Machine Interface (HMI) serves as the primary touchpoint for your users, defining both their experience and the overall reliability of your system. Our design approach focuses on creating high-performance visual solutions that remain legible and responsive in high-stakes environments, ranging from bright outdoor sunlight to sterile medical theatres.

- Tailored Display Solutions: Create custom TFT LCDs, micro OLEDs, or near-eye displays with high brightness (up to 3,000 nits) and optical bonding for durability and clarity.

- Interactive Interfaces: Design intuitive HMIs with Projected Capacitive (PCAP) touchscreens, supporting multi-touch, glove use, and operation in wet or EMI-heavy environments.

- Integrated Systems: Combine displays, touch controllers, and embedded electronics for seamless, user-friendly interfaces in medical, automotive, or industrial applications.

Mechanical and Enclosure Design

A product’s physical architecture is just as critical as its internal electronics, especially when deployed in unpredictable or harsh conditions. Our mechanical engineering team focuses on creating a robust protective shell that balances structural integrity with thermal efficiency, ensuring your hardware remains operational and accessible throughout its lifecycle.

- Rugged Enclosures: Engineer IP-rated (up to IP68) enclosures for dust, water, and vibration resistance, meeting MIL-STD and industrial standards.

- Compact and Lightweight Designs: Optimise form factors for space-constrained applications like wearables, aerospace, and robotics without sacrificing durability.

- Material Expertise: Select advanced materials for thermal management, weight reduction, and environmental resilience, ensuring compliance with ESG goals.

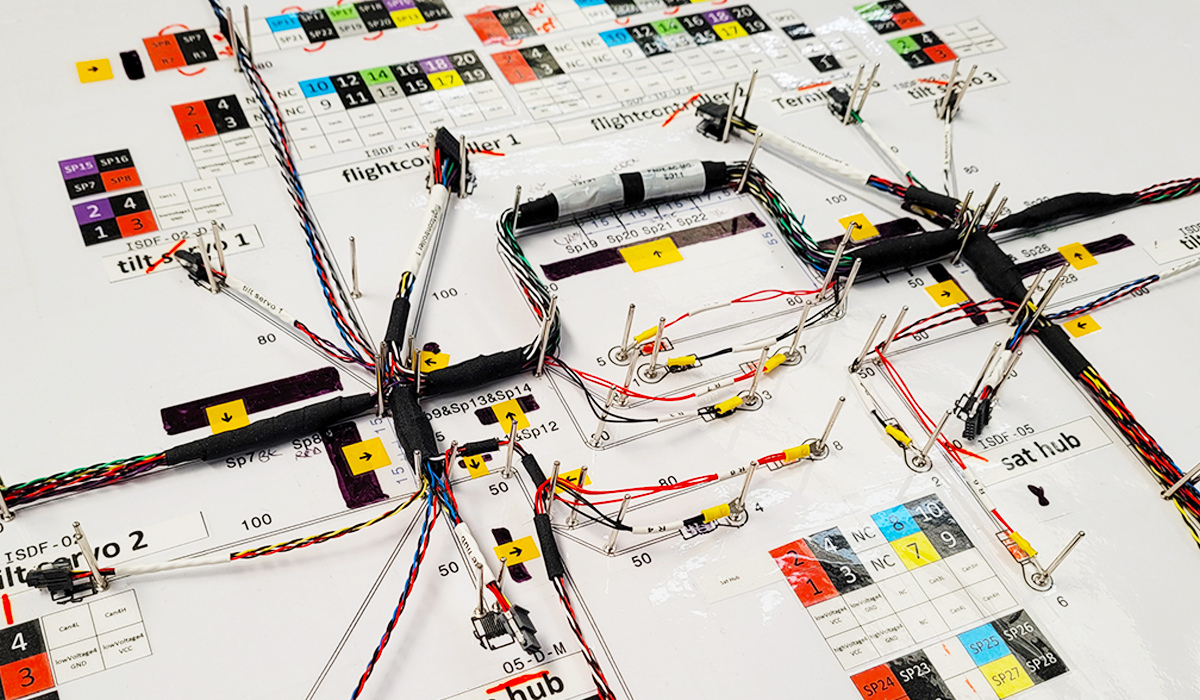

Cable and Connectivity Design

In complex electronic systems, the cables and connectors are often the most vulnerable points of failure, particularly when subjected to movement, moisture, or electrical interference. Our connectivity design service focuses on engineering bespoke pathways that guarantee signal integrity and mechanical durability, ensuring your integrated components communicate flawlessly under any conditions.

- Custom Interconnects: Design overmoulded, waterproof, and high-flex cable assemblies for reliable signal transmission in defence, aerospace, and industrial systems.

- High-Performance Connectors: Develop RF, LVDS, and fine-pitch connectors with EMI shielding for secure, high-speed data transfer.

- System Integration: Ensure seamless connectivity between displays, embedded systems, and peripherals for a fully cohesive product.

Testing and Validation

Before any product reaches the manufacturing floor, it must undergo a rigorous period of verification to ensure it can survive the physical and regulatory demands of its intended environment. Our testing and validation phase is designed to identify and eliminate potential failure points early, providing the empirical evidence needed to guarantee long-term field reliability and global market compliance.

- Environmental Testing: Validate designs under extreme conditions (-40 °C to +85 °C), shock, vibration, and humidity to ensure reliability.

- Compliance and Certification: Meet stringent standards like ISO 13485, MIL-STD, CE, FCC, and EN50155 for global market readiness.

- Iterative Refinement: Use real-world testing and customer feedback to optimise designs for performance, manufacturability, and cost-efficiency.

Why Choose RDS for Product Design?

- Tailored Innovation: Our designs are 98% custom, ensuring your product aligns perfectly with your vision, application, and industry requirements.

- End-to-End Expertise: From concept to production, our UK- and US-based teams manage every stage under strict quality controls, with NDA protection for sensitive projects.

- Proven Reliability: Solutions engineered for harsh environments, delivering consistent performance in mission-critical applications like defence and medical systems.

- Global Partnerships: Collaborations with industry leaders like Kontron and AAEON provide access to cutting-edge components and reliable supply chains.

- Sustainability Focus: Eco-friendly materials and energy-efficient designs align with modern regulatory and environmental standards.

We have designed transformative products like rugged control systems for military applications, IoT- enabled automation for smart factories, and medical-grade HMIs for diagnostics, proving our ability to deliver precision and innovation.