RDS Manufacturing Capabilities:

Precision Production for Demanding Applications

Our state-of-the-art manufacturing capabilities turn custom electronics, displays, and embedded systems into reliable, production-ready solutions.

From rapid prototypes to high-volume production, we build every product to meet the highest standards of quality, durability, and performance, even in the most demanding environments.

Our global manufacturing network, rigorous quality control, and deep engineering expertise make us a trusted partner for bringing complex designs to life. Whether you need rugged display solutions, custom embedded systems, or specialised cable harnesses, we deliver scalable and cost-effective solutions tailored to your requirements.

Advanced Production Facilities

To support your global manufacturing and supply chain needs, we leverage a diverse, multi-site operational strategy that combines local agility with international scale. By maintaining a strong presence across both the UK and Europe, we provide our partners with the benefit of regional engineering expertise, reduced lead times, and seamless communication, all while maintaining a robust global footprint.

- Global Reach, Local Precision: State-of-the-art manufacturing sites in the UK, Europe, and the Far East ensure rapid turnaround and supply chain resilience.

- Cleanroom Assembly: ISO 13485 compliant cleanrooms for medical-grade and high-precision electronics, ensuring contamination-free production.

- Scalable Capacity: From low-volume prototypes to high-volume production runs, we adapt to your project’s scale with consistent quality.

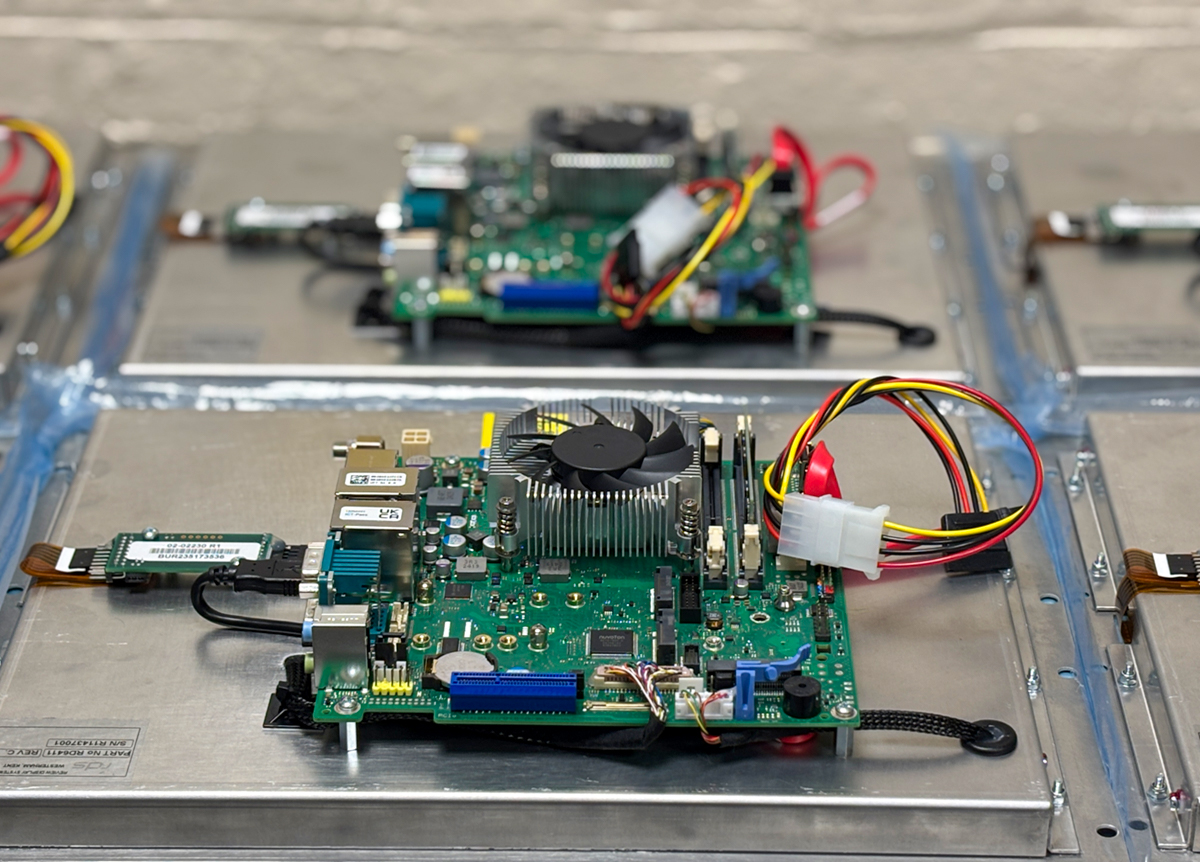

Custom Electronics Manufacturing

At RDS, we provide a comprehensive electronics manufacturing service that bridges the gap between complex engineering designs and high-quality finished products. Our UK and European facilities are equipped with the latest technology to ensure that every component, from the smallest surface-mount device to the most intricate display assembly, is built to exacting industrial standards.

- PCB Assembly: Surface-mount (SMT) and through-hole assembly with automated pick-and-place systems for high accuracy and repeatability.

- Embedded Systems Production: Full assembly of single-board computers (SBCs), Box PCs, and custom controllers, integrated with firmware and software.

- Display Integration: Precision assembly of TFT LCDs, micro OLEDs, and touchscreens with optical bonding for enhanced durability and clarity.

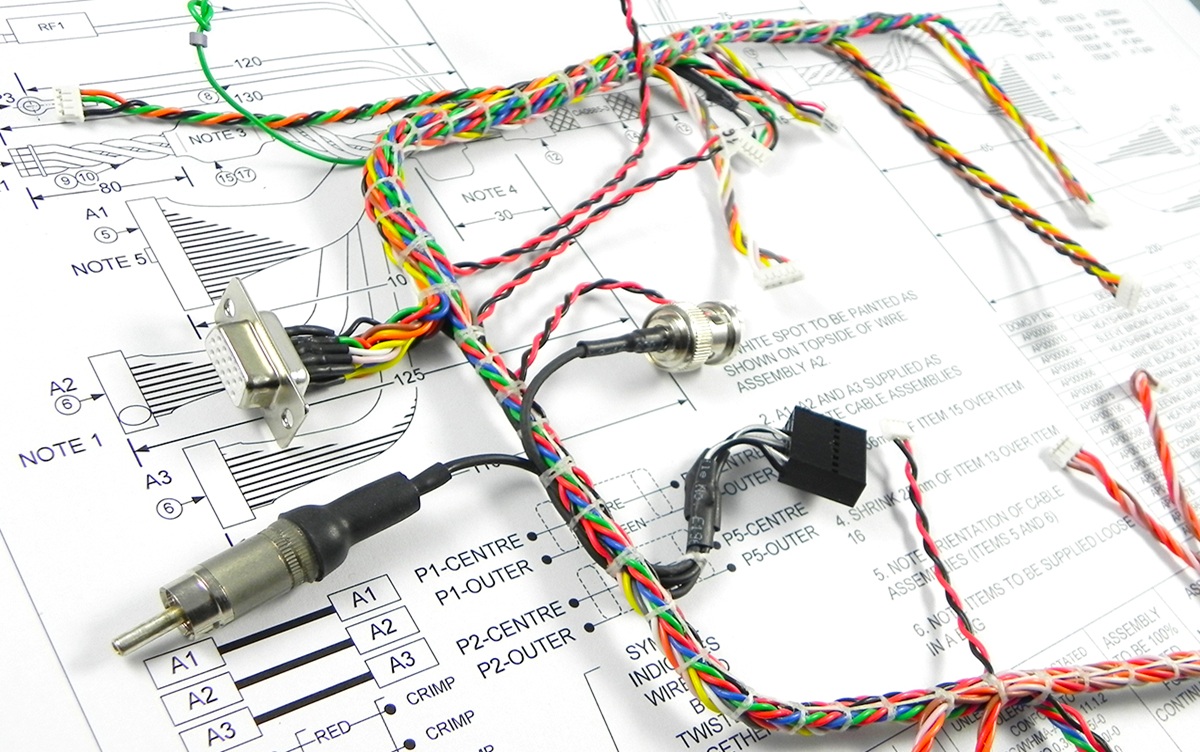

Cable and Connector Assembly

Reliable connectivity is the lifeline of any integrated system, particularly when operating in volatile or high-interference environments. We provide bespoke cabling solutions engineered to withstand mechanical stress and environmental extremes, ensuring that your data and power signals remain uncompromised.

- Custom Harnesses: Overmoulded, waterproof (IP68), and high-flex cable assemblies tailored for defense, aerospace, and industrial applications.

- High-Frequency Interconnects: RF and microwave cables with low insertion loss, tested for signal integrity and EMI shielding.

- Automated Production: Cutting, crimping, and testing equipment ensure consistent quality and fast delivery for complex wire looms.

Enclosure and Mechanical Assembly

To ensure long-term reliability in the field, electronic systems must be housed in mechanical structures that offer both protection and seamless functional integration. Our mechanical assembly services focus on bridging the gap between delicate internal components and the harsh external environments they must withstand.

- Rugged Enclosures: Custom-designed, IP-rated enclosures for dust, water, and vibration resistance, built to MIL-STD and industrial standards.

- Precision Machining: CNC machining and 3D printing for bespoke components, ensuring exact fit and functionality.

- Integrated Systems: Complete assembly of HMIs, combining displays, embedded electronics, and cabling into seamless, ready-to-deploy units.

Quality Assurance and Testing

To ensure long-term reliability in mission-critical environments, our manufacturing process is underpinned by a rigorous Quality Assurance (QA) framework. We employ a combination of automated validation and manual inspection to guarantee that every unit leaving our facility meets the exacting standards required for global deployment in the medical, defence, and industrial sectors.

- Rigorous Testing Protocols: Environmental (temperature, humidity, shock), EMI, and functional testing to ensure reliability in extreme conditions (-40°C to +85°C).

- Certifications: Compliance with ISO 9001, ISO 14001, ISO 13485, MIL-STD, CE, FCC, and EN50155 standards for global deployment.

- Traceability and Documentation: Full component traceability and detailed reporting for regulatory compliance and obsolescence management.

Supply Chain and Obsolescence Management

In an era of global market volatility, maintaining a stable and resilient supply chain is essential for long-term product viability. We provide a strategic procurement service that focuses on securing high-quality components while proactively managing the risks associated with technical phase-outs and market fluctuations.

- Global Sourcing: Partnerships with leading component suppliers ensure access to high-quality, long-lifecycle parts.

- Obsolescence Planning: Proactive strategies to mitigate component shortages, ensuring your product’s longevity and availability.

- Cost Optimisation: BOM reviews and value engineering to reduce costs without compromising quality or performance.

Why Choose RDS for Manufacturing?

- End-to-End Expertise: From design collaboration to final assembly, our in-house teams manage every stage under strict quality controls, with NDA protection for sensitive projects.

- Uncompromising Reliability: Products built to withstand extreme environments, ensuring uptime in mission-critical applications like defence and medical systems.

- Global Scalability: Our worldwide manufacturing network supports rapid prototyping, small-batch runs, and large-scale production with consistent quality.

- Sustainability Commitment: Eco-friendly processes and materials minimise environmental impact, aligning with ESG and regulatory standards.

- Trusted Partnerships: Collaborations with industry leaders like Kontron and AAEON provide access to cutting-edge technology and reliable supply chains.

We have manufactured solutions for high-stakes applications, including rugged control systems for military vehicles, IoT-enabled automation for smart factories, and medical-grade electronics for diagnostics. Our ability to deliver precision at scale ensures your project succeeds on time and within budget.