Motion Control Systems and Stepper Motors for Industrial, Medical, and Robotics Applications

11 October, 2025

Motion Control Systems and Stepper Motors for Industrial, Medical, and Robotics Applications By Daniel Burke, Marketing Manager at RDS.

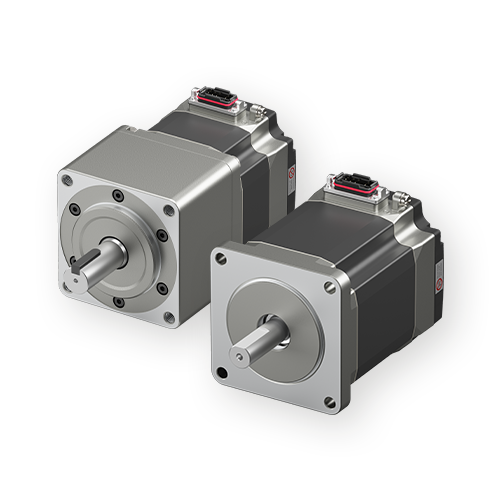

Motion control systems are the backbone of modern automation, enabling precise, efficient, and reliable movement in industries ranging from manufacturing to healthcare. Review Display Systems (RDS), a trusted supplier of industrial automation components, offers a range of AC and DC stepper motors designed for demanding applications such as industrial machinery, medical devices, robotics, warehousing, and factory automation. This article explores the role of motion control, the characteristics of AC and DC stepper motors, and their applications across these sectors, highlighting how RDS’s solutions drive innovation and performance.

Understanding Motion Control

Motion control is a subfield of automation that manages the position, velocity, and torque of mechanical systems using actuators, motors, and controllers. It encompasses open-loop systems, where commands are sent without feedback (e.g., stepper motors), and closed-loop systems, which use sensors like encoders to adjust for errors (e.g., servo motors). Motion control is critical in applications requiring high precision, repeatability, and efficiency, such as robotics, CNC machines, and automated warehousing. According to industry insights, motion control systems can increase process speeds by up to 50% compared to mechanical systems, making them essential for Industry 4.0.

RDS provides motion control solutions that integrate motors, drivers, and controllers, optimised for seamless coordination in complex tasks. These systems are designed for durability, high-speed communication, and compatibility with programmable logic controllers (PLCs) and human-machine interfaces (HMIs), ensuring scalability and precision across industries.

AC and DC Stepper Motors: Characteristics and Benefits

Stepper motors are a cornerstone of motion control, valued for their ability to divide a full rotation into precise steps, enabling accurate positioning without feedback in open-loop systems. RDS offers both AC and DC stepper motors, each suited to specific applications based on power requirements, torque, and environmental factors.

- AC Stepper Motors:

- Characteristics: Powered by alternating current, AC stepper motors are synchronised with the supply current’s frequency, providing constant speed under varying loads. They are typically compact, cost-effective, and robust, with high torque at low speeds.

- Advantages: AC steppers are less expensive than servo motors and excel in applications requiring consistent speed and point-to-point positioning. They are durable, with long service lives, and suitable for hostile environments due to their simple design.

- Limitations: AC steppers may lack the dynamic response of servo motors and are less suited for high-speed applications or those requiring complex motion profiles. Inertia ratio and settling time must be considered to avoid stalling.

- DC Stepper Motors:

- Characteristics: Powered by direct current, DC stepper motors offer precise control via digital pulses, dividing rotation into equal steps (e.g., 1.8° per step for 200 steps per revolution). They often feature microstepping for smoother motion and higher resolution.

- Advantages: DC steppers provide high starting torque, variable speed control, and precise positioning, making them ideal for compact, low-speed applications. They are energy-efficient, reducing heat, and integrate well with modern controllers for noise-free operation (e.g., technologies like StealthChop).

- Limitations: DC steppers may stall under high shock loads or heavy payloads unless paired with advanced hybrid technologies. They are less suited for high-power applications compared to AC motors or servos.

RDS’s stepper motors are engineered for reliability, with features like closed-loop options for enhanced accuracy and integrated drivers for simplified setup. These motors are compatible with industry-standard interfaces like EtherCAT and RS485, ensuring seamless integration into automation systems.

Applications Across Industries

RDS’s AC and DC stepper motors power a wide range of applications, leveraging their precision and efficiency to meet the unique demands of industrial, medical, robotics, warehousing, and factory automation sectors.

- Industrial Applications:

- Use Case: In packaging and conveying systems, stepper motors drive precise point-to-point movements, such as positioning products for inspection or controlling conveyor speeds. For example, a packaging machine might use a DC stepper motor to move products to exact locations for sealing, reducing errors and improving throughput.

- Benefits: AC steppers provide consistent speed for continuous processes, while DC steppers offer fine-tuned positioning for tasks like labeling or cutting. Their compact size and low cost make them economical for high-volume production lines.

- RDS Advantage: RDS supplies stepper motors with customisable torque and speed settings, ensuring compatibility with diverse industrial machinery, from textile looms to semiconductor fabrication.

- Medical Uses:

- Use Case: Stepper motors are critical in medical devices like diagnostic equipment, surgical robots, and laboratory automation. For instance, a DC stepper motor might drive a carousel in a blood analyser, precisely positioning test tubes for reagent dispensing, or control the movement of an MRI scanner’s patient table.

- Benefits: DC steppers excel in medical applications due to their high precision, low noise, and ability to operate in sterile environments (e.g., sterilisable motors). AC steppers are used in larger diagnostic machines requiring consistent motion. Their energy efficiency minimises heat, critical for patient safety.

- RDS Advantage: RDS offers microstepping stepper motors with s-shaped acceleration ramps, ensuring vibration-free motion for delicate tasks like pipetting or laser positioning in optometry.

- Robotics:

- Use Case: In robotic arms and collaborative robots (cobots), stepper motors control joints and end-effectors for tasks like welding, assembly, or pick-and-place operations. A DC stepper motor might drive a camera platform for high-precision vision systems, while an AC stepper powers a robotic base for stable movement.

- Benefits: DC steppers provide high torque and precise positioning for intricate movements, while AC steppers support heavier payloads in industrial robots. Their integration with closed-loop controllers enhances accuracy for complex motion profiles.RDS Advantage: RDS’s stepper motors are compact and networkable, supporting multi-axis coordination in robotics. They are designed for durability in hostile environments, such as automotive assembly lines.

- Warehousing:

- Use Case: Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) in warehouses rely on stepper motors for navigation and material handling. For example, a DC stepper motor might control an AGV’s steering, while an AC stepper drives its conveyor for sorting packages.

- Benefits: DC steppers enable precise navigation in complex warehouse layouts, while AC steppers provide reliable, high-torque motion for heavy loads. Their compact design reduces AGV weight, improving energy efficiency.

- RDS Advantage: RDS supplies integrated stepper motor solutions with built-in drivers, minimising cabling and simplifying AGV design. These motors support high-speed communication for real-time coordination with warehouse management systems.

- Factory Automation:

- Use Case: In factory automation, stepper motors drive conveyors, pick-and-place systems, and CNC machines. A DC stepper might control a 3D printer’s print head, while an AC stepper powers a milling machine’s spindle for consistent rotation.

- Benefits: Stepper motors enhance factory efficiency by reducing cycle times and enabling rapid reconfiguration for different products. Their precision ensures consistent quality in tasks like drilling or engraving.

- RDS Advantage: RDS offers stepper motors with advanced diagnostic capabilities and predictive maintenance features, minimising downtime in automated factories. Their solutions integrate with PLCs and SCADA systems for seamless operation.

Comparison with Other Motion Control Solutions

While stepper motors are cost-effective and precise, they are often compared to servo motors, which offer higher dynamic response and closed-loop feedback. Servo motors, as noted by industry experts, are the “top of the food chain” for applications needing rapid response or high power (>1 HP), but they are more expensive and complex. Stepper motors, particularly those from RDS, strike a balance by offering sufficient precision for most applications at a lower cost, especially in open-loop configurations.

In medical applications, stepper motors compete with brushless DC motors, which offer smoother motion but require more complex controllers. RDS’s microstepping technology mitigates this gap, providing near-servo-like smoothness for devices like infusion pumps. In warehousing, stepper motors are preferred over hydraulic systems for their cleanliness and energy efficiency, as seen in electro-hydraulic actuators (EHAs) driven by steppers.

Why Choose RDS for Stepper Motors?

RDS stands out as a supplier due to our focus on high-quality, application-specific solutions. Our AC and DC stepper motors are designed for:

- Precision: Microstepping and closed-loop options ensure accuracy in demanding tasks.

- Durability: Weather-sealed and robust, suitable for hostile environments like factories or outdoor AGVs.

- Integration: Compatibility with EtherCAT, RS485, and PLCs simplifies system design.

- Support: RDS provides application engineering support, helping customers select motors that optimise performance and longevity.

Our motors are also cost-effective, with modular designs that reduce assembly time and maintenance costs. For example, integrated stepper motors (motor + driver in one housing) streamline setup for robotics and medical devices, saving time and reducing cabling complexity.

Future Trends and Conclusion

As industries move toward Industry 4.0, motion control systems are evolving with AI and machine learning to enable autonomous decision-making and predictive maintenance. Stepper motors, particularly DC models, are adapting with higher microstep resolutions and energy-efficient designs to meet these demands. At RDS we are well-positioned to support this transition, offering scalable solutions that integrate with smart factory technologies like SCADA and IoT.

In conclusion, RDS’s AC and DC stepper motors are versatile, cost-effective solutions for motion control in industrial applications, medical devices, robotics, warehousing, and factory automation. Their precision, durability, and ease of integration make them ideal for tasks ranging from robotic assembly to diagnostic imaging. For industries seeking smarter, faster, and more sustainable automation, RDS’s motion control solutions pave the way for a more efficient future.

For more information regarding RDS and our range of motors and controller please give us a call on 01959 563 345