Industrial Display Technologies: Applications and Advantages

30 May, 2025

Industrial display technologies have evolved significantly to meet the diverse needs of modern industries, from manufacturing and automation to transportation and healthcare. These displays must withstand harsh environments, deliver high performance, and cater to specific application requirements. This article explores the primary industrial display technologies currently in use, their applications, advantages, and how Review Display Systems leverages these technologies to design and build complete display systems.

- E-Paper Displays (EPDs)

- Liquid Crystal Displays (LCDs)

- Organic Light-Emitting Diode (OLED) Displays

- Touchscreen Technologies

Overview

Liquid Crystal Displays (LCDs) are among the most widely used industrial display technologies. They utilise liquid crystals to modulate light and produce images. LCDs are available in various configurations, such as Twisted Nematic (TN), In-Plane Switching (IPS), and Vertical Alignment (VA), each offering distinct performance characteristics.

Applications

- Industrial Automation: LCDs are used in Human-Machine Interfaces (HMIs) for controlling machinery and monitoring processes.

- Medical Devices: High-resolution LCDs display critical data in diagnostic equipment and patient monitoring systems.

- Transportation: LCDs are employed in dashboard displays, ticketing systems, and passenger information screens.

- Retail and POS Systems: Touch-enabled LCDs power interactive kiosks and point-of-sale terminals.

Advantages

- Versatility: Available in a wide range of sizes, resolutions, and configurations.

- Energy Efficiency: Consumes less power compared to older technologies like CRTs.

- High Resolution and Clarity: IPS and VA panels offer excellent colour accuracy and wide viewing angles.

- Cost-Effectiveness: Mature technology with competitive pricing for most applications.

Why Choose LCDs?

LCDs are ideal for applications requiring reliable performance, high resolution, and cost efficiency. They are well-suited for indoor environments and can be enhanced with features like touchscreens, anti-glare coatings, and ruggedised enclosures for industrial use.

Overview

OLED displays use organic compounds that emit light when an electric current is applied. Unlike LCDs, OLEDs do not require a backlight, resulting in thinner, lighter displays with superior contrast and colour performance.

Applications

- High-End Industrial Equipment: OLEDs are used in precision instruments requiring vibrant visuals and compact designs.

- Automotive: Dashboard and infotainment systems leverage OLEDs for their flexibility and high contrast.

- Wearable Devices: Compact OLEDs power rugged wearable interfaces for industrial workers.

- Digital Signage: OLEDs deliver eye-catching displays in retail and public spaces.

Advantages

- Superior Image Quality: Deep blacks, high contrast ratios, and vibrant colours due to self-emissive pixels.

- Flexibility: Can be manufactured on flexible substrates, enabling curved or foldable displays.

- Fast Response Times: Ideal for dynamic content and fast-moving visuals.

- Thin and Lightweight: No backlight reduces bulk, making OLEDs suitable for space-constrained applications.

Why Choose OLEDs?

OLEDs are preferred for applications where image quality, flexibility, and compact design are critical. They excel in environments requiring high contrast and are increasingly adopted in premium industrial systems despite their higher cost compared to LCDs.

Overview

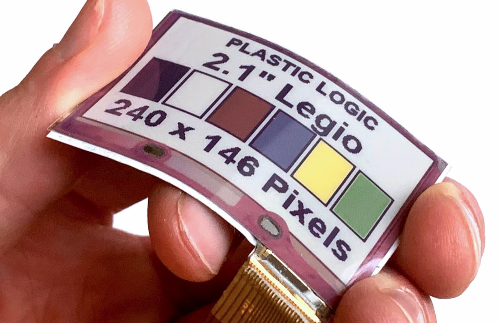

E-Paper Displays, also known as electronic ink displays, mimic the appearance of printed paper. They use microcapsules filled with charged particles to create low-power, reflective displays.

Applications

- Logistics and Warehousing: E-Paper displays are used in electronic shelf labels and inventory management systems.

- Public Information Systems: Bus stops and train stations use EPDs for low-power, sunlight-readable signage.

- Industrial Handhelds: Rugged handheld devices employ E-Paper for battery-efficient displays.

- Smart Tags: Asset tracking and IoT devices integrate E-Paper for minimal power consumption.

Advantages

- Ultra-Low Power Consumption: Only consumes power when the display content changes, ideal for battery-powered devices.

- Sunlight Readability: Reflective nature ensures excellent visibility in bright environments.

- Wide Viewing Angles: Mimics paper, providing consistent readability from various angles.

- Durability: No glass backlight, making EPDs robust for rugged applications.

Why Choose E-Paper?

E-Paper is the go-to choice for applications prioritising energy efficiency and sunlight readability. It’s particularly suited for static or semi-static content in outdoor or battery-operated devices.

Touchscreen Technologies

Overview

While not a display technology in itself, touchscreen interfaces are integral to many industrial displays. Common touchscreen technologies include Resistive, Capacitive (including Projected Capacitive), Infrared, and Surface Acoustic Wave (SAW).

Applications

- HMIs in Manufacturing: Resistive and capacitive touchscreens enable intuitive control of machinery.

- Medical Interfaces: Capacitive touchscreens provide responsive, hygienic interfaces for medical equipment.

- Retail and Kiosks: Projected Capacitive touchscreens support multi-touch gestures for interactive customer experiences.

- Outdoor Applications: Infrared and SAW touchscreens are used in rugged, weather-resistant kiosks.

Advantages

- Resistive: Cost-effective, works with gloves or styluses, suitable for harsh environments.

- Capacitive: High sensitivity, supports multi-touch, and offers a premium user experience.

- Infrared and SAW: Durable, ideal for large displays or outdoor use where ruggedness is key.

Why Choose Touchscreens?

The choice of touchscreen technology depends on the environment and user interaction needs. Resistive is best for cost-sensitive, gloved-operation scenarios, while capacitive suits high-end, responsive interfaces. Infrared and SAW are ideal for large, durable systems

Transparent and Flexible Displays

Overview

Emerging technologies like transparent LCDs and flexible OLEDs are gaining traction in niche industrial applications. Transparent displays allow users to see through the screen while displaying information, while flexible displays can bend or conform to non-flat surfaces.

Applications

- Smart Manufacturing: Transparent displays overlay real-time data on equipment or production lines.

- Retail: Transparent OLEDs create interactive product showcases in storefronts.

- Automotive: Flexible displays integrate into curved dashboards or head-up displays (HUDs).

- Wearables and IoT: Flexible displays power innovative, ergonomic industrial devices.

Advantages

- Innovative Design: Transparent displays enable augmented reality-like experiences.

- Adaptability: Flexible displays conform to unique shapes, enhancing design flexibility.

- Engaging Visuals: Both technologies offer high visual appeal for modern applications.

Why Choose Transparent or Flexible Displays?

These cutting-edge technologies are chosen for futuristic, design-driven applications where traditional flat displays fall short. They are ideal for industries pushing the boundaries of user interaction and aesthetics.

Review Display Systems: Tailored Solutions for Any Technology

Review Display Systems (RDS) specialises in designing and building complete display systems based on the technologies outlined above. With decades of experience, RDS offers end-to-end solutions, from concept to production, tailored to the specific needs of industrial applications. Whether it’s a rugged LCD-based HMI for a factory floor, an energy-efficient E-Paper display for logistics, or a flexible OLED for automotive innovation, RDS combines expertise in display technology, touch integration, and ruggedisation to deliver reliable, high-performance systems.

Why Choose Review Display Systems?

- Customisation: RDS engineers bespoke solutions, integrating displays, touchscreens, and enclosures to meet exact specifications.

- Ruggedisation: Systems are designed to withstand extreme temperatures, vibrations, and harsh environments.

- Comprehensive Support: From prototyping to mass production, RDS provides full lifecycle support.

- Technology Agnostic: RDS leverages the best display technology for the application, ensuring optimal performance and cost-efficiency.

- Complete system solutions supported from a global manufacturing base.

- Software, hardware, enclosures, cabling, manufacturing, RDS can be a one stop shop for all you product needs.

Conclusion

The choice of industrial display technology depends on the application’s requirements, environment, and budget. LCDs offer versatility and cost-effectiveness, OLEDs provide unmatched image quality, E-Paper excels in low-power scenarios, touchscreens enhance interactivity, and transparent/flexible displays push innovation boundaries. RDS stands out as a trusted partner, capable of designing and building complete systems that harness these technologies to meet the demands of modern industries. By understanding the strengths of each display type, businesses can make informed decisions to optimise performance and drive operational success.

For more information on custom solutions please give us a call on 01959 563 345